Directional control valves are crucial in regulating fluid flow within a hydraulic or pneumatic system. They control fluid flow's direction, start, and stop, enabling the smooth operation of various industrial processes. Several directional control valves are available, each designed to meet specific system requirements. Let's explore some of the common types:

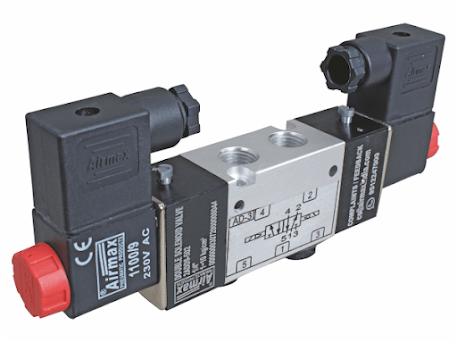

Spool valves: These valves consist of a cylindrical spool that slides within a housing. By positioning the spool, the flow path can be controlled, allowing fluid to flow through different ports.

Poppet valves: Poppet valves use a disc or a cone-shaped element that opens or closes to regulate flow. They are known for their quick response and high flow capacity, making them suitable for high-pressure applications.

Rotary valves: As the name suggests, these valves use a rotary motion to control fluid flow. They typically have a cylindrical rotor with channels that align with various ports, directing the flow accordingly.

Ball valves: Ball valves use a rotating ball with a bore to control the flow. When the ball is aligned with the port, fluid can flow; when it is rotated, the flow is blocked.

Sliding plate valves: These valves control the flow path using a sliding plate. The plate has slots or holes that align with the ports to allow fluid flow.

Proportional valves: Directional control valves regulate flow based on a variable input, such as an electrical or pressure signal. They provide precise control over flow rates, making them suitable for applications that require fine adjustments.

Directional control valves are vital in various industries, including manufacturing, construction, and transportation. They ensure the efficient and safe operation of hydraulic and pneumatic systems, enabling precise control over fluid flow and direction.

In summary, directional control valves are available in different types, including spool, poppet, rotary, ball, sliding plate, and proportional valves. Each type offers unique features and advantages, catering to specific system requirements. Whether it's controlling the movement of actuators or regulating flow in complex systems, directional control valves play a crucial role in maintaining smooth operations. So, to optimize your hydraulic or pneumatic system, choosing the right directional control valve is essential to ensure optimal performance.

How Do Directional Control Valves Work?

Directional control valves are vital components in hydraulic systems that regulate the flow of fluids, such as oil or water, in a desired direction. They play a crucial role in determining the path and timing of fluid flow, allowing for precise control over the operation of various hydraulic actuators. Here's an overview of how directional control valves work:

Purpose: Directional control valves are designed to direct fluid flow from an input port to one or more output ports, selectively allowing or blocking the passage of fluid based on the valve's position.

Spool Design: Most directional control valves employ a spool mechanism that slides within a housing, controlling the flow passages and directing fluid. The spool has different landings and channels that correspond to various flow paths.

Positions: Directional control valves typically have two or more positions, such as "open" and "closed." In the open position, fluid can flow through specific channels, while in the closed position, the flow is blocked.

Actuation Methods: These valves can be actuated mechanically, electrically, pneumatically, or hydraulically, depending on the specific application. The actuator moves the spool to change the valve's position and control the fluid flow.

Control Mechanisms: Directional control valves can be manually operated or controlled by automated systems, such as solenoids, hydraulic pilots, or computerized control units, which enable precise and responsive control over the valve's position.

Applications: Directional control valves find extensive use in various industries, including manufacturing, construction, agriculture, and automotive, where they control the movement of cylinders, motors, and other hydraulic components.

Directional control valves are essential for achieving efficient and controlled hydraulic operations. By precisely directing the fluid flow, these valves enable the proper functioning of hydraulic systems, ensuring smooth and reliable operation. The directional control valve is critical for controlling fluid power in simple or complex systems.

When Should You Use A Directional Control Valve?

A directional control valve is an essential component in various hydraulic and pneumatic systems, allowing for the control and regulation of fluid flow. Understanding when to use a directional control valve is crucial for optimizing the performance and efficiency of your system. Here are some key situations where the implementation of a directional control valve is necessary:

Changing fluid direction: Directional control valves are primarily used to control the flow direction of fluids in hydraulic and pneumatic systems. When you need to alter the fluid flow path, such as redirecting it from one actuator to another or reversing the direction of a cylinder, a directional control valve is indispensable.

Controlling fluid flow: Directional control valves enable precise regulation of fluid flow rates. Whether you need to increase, decrease, or completely shut off the flow, these valves offer the flexibility to achieve accurate control. This feature is particularly useful in applications requiring controlled movement or speed adjustment.

Actuator selection: Directional control valves allow you to choose which actuators are active in your system. Using the valve to control which actuators receive fluid flow, you can selectively activate or deactivate specific components according to your system requirements.

Safety and emergencies: Directional control valves are instrumental in emergency stop scenarios and safety measures. Using these valves, you can quickly shut off the fluid flow to specific system parts, isolating potential hazards or preventing further damage.

Sequential operations: Directional control valves play a critical role in systems that require a specific sequence of events or operations. They enable the proper sequencing of actuators, ensuring that each actuator engages or disengages in the correct order for optimal performance.

In summary, a directional control valve is essential when changing fluid direction, controlling fluid flow, selecting actuators, addressing safety concerns, or performing sequential operations in your hydraulic or pneumatic system. Incorporating this valve can enhance your system's overall efficiency, functionality, and safety.

The Benefits of Using a Directional Control Valve

A directional control valve is a critical component in various industrial and manufacturing applications, offering precise control over the direction and flow of fluids or gasses. Whether it's hydraulic, pneumatic, or other fluid power systems, directional control valves provide numerous benefits that enhance efficiency and performance. Here are some key advantages of using a directional control valve:

Enhanced Control: Directional control valves allow operators to regulate the flow of fluids or gasses, enabling precise control over the direction and speed of actuators. This feature ensures accurate movement and positioning, improving productivity and operational efficiency.

Versatility: These valves come in various configurations, including spool, poppet, and rotary valves, offering versatility to meet specific system requirements. They can be customized with different port sizes, flow rates, and pressure ratings, allowing seamless integration into diverse applications.

Safety and Reliability: Directional control valves are crucial in ensuring the safety and reliability of hydraulic and pneumatic systems. They enable emergency shutdowns, prevent system overloads, and regulate pressure levels, protecting equipment and minimizing the risk of accidents.

Energy Efficiency: Directional control valves optimize energy usage in fluid power systems by controlling the flow direction and speed. They allow for precise activation and deactivation of actuators, reducing unnecessary energy consumption and improving overall system efficiency.

Simplified Maintenance: Directional control valves are designed for easy maintenance and replacement. Their modular construction and standardized interfaces enable quick troubleshooting and part replacements, minimizing downtime and enhancing system reliability.

In summary, directional control valves offer a range of benefits, including enhanced control, versatility, safety, energy efficiency, and simplified maintenance. These advantages make them indispensable components in fluid power systems across various industries, ensuring optimal performance and productivity. Incorporating a directional control valve into your system can significantly enhance efficiency and effectiveness.

Directions Control Valve FAQs

Are you looking for answers to common questions about directional control valves? Look no further! This article has compiled a list of frequently asked questions (FAQs) to help you better understand directional control valves. Whether you are a beginner or an experienced professional, these FAQs will provide valuable insights into this essential component of fluid power systems.

Here are some of the most commonly asked questions about directional control valves:

What is a directional control valve?

A directional control valve is used to control the direction of fluid flow in a hydraulic or pneumatic system.

How does a directional control valve work?

A directional control valve typically consists of a movable spool or poppet that controls fluid flow through different ports to change the direction of fluid flow.

What are the applications of directional control valves?

Directional control valves are widely used in various industries such as manufacturing, construction, agriculture, and transportation for controlling the movement of actuators, such as cylinders and motors.

What are the types of directional control valves?

Different types of directional control valves, including spool, poppet, and rotary valves, each with advantages and applications.

What factors should I consider when selecting a directional control valve?

Factors to consider include the fluid type, flow rate, pressure rating, number of ports and positions, and the required actuator operation.

What are the common problems faced with directional control valves?

Common issues include leakage, sticking or jamming of the spool, insufficient flow, and erratic valve operation.

By understanding these FAQs, you can better understand directional control valves and their importance in fluid power systems. Consult with experts or manufacturers when selecting and troubleshooting directional control valves to ensure optimal performance and safety.

No comments:

Post a Comment