If you work with air compressors, then you know that pneumatic couplers are an essential part of the system. But what exactly are pneumatic couplers? What are the different types? How do you install and maintain them? If you encounter a problem, what should you do?

We are here to answer all of your questions, so don't worry. In this blog post, we'll give you everything you need to know about pneumatic couplers. So read on to learn more!

What is a pneumatic coupler?

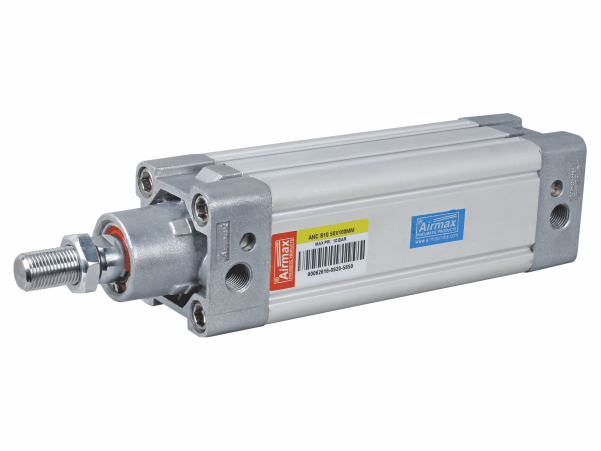

A pneumatic coupler is a device that is used to connect two pieces of equipment using compressed air. The most common type of pneumatic coupler is the quick-connect coupler, which is used to connect air tools to an air compressor. Quick-connect couplers have a male and female end and are connected by pushing the two ends together. There are also push-to-connect (PTC) couplers, which have a male end and a female end that are connected by pushing the male end into the female end.

Pneumatic couplers are used in a variety of applications, including construction, automotive repair, and manufacturing. They are often used to connect air tools to an air compressor or to connect two pieces of equipment that use compressed air. Pneumatic couplers can be made from a variety of materials, including brass, aluminum, stainless steel, and plastic.

Why do you need a pneumatic?

A pneumatic coupling is a device used to connect two pieces of equipment or tubing. Pneumatic couplings are commonly used in the medical and automotive industries, as well as in many other applications where a quick, secure connection is needed. There are many different types of pneumatic couplings available on the market, so it is important to choose the right one for your needs.

One of the most common reasons to use a pneumatic coupling is to connect two pieces of equipment that operate at different pressures. For example, if you were connecting an air compressor to an air-powered tool, you would need a coupling that could withstand the high pressure of the compressor. Another common reason for using a pneumatic coupling is to connect two pieces of tubing. This might be necessary if you were connecting a length of tubing to an air-powered tool or machine.

Pneumatic couplings are available in a variety of sizes and styles, so it is important to select the right one for your application. If you are unsure which type of coupling you need, it is always best to consult with a professional before making your purchase.

Types of pneumatic couplers

There are many different types of pneumatic couplers available on the market. The most common type is the quick connect coupling, which consists of two sleeves that interlock. Another popular type is the push-to-connect coupling, which has a button or lever that is pushed to release the connection. There are also threaded couplings, which screw together to create a tight seal. Choosing the right type of coupling depends on the application and the needs of the user.

How to install a pneumatic coupler

There are two ways to install a pneumatic coupling: quick connect and push-to-connect.

Quick connect installation is the easiest and most common method. It simply involves pushing the two ends of the coupling together until they click into place. This type of connection is very secure and can be used in a variety of applications.

Push-to-connect installation is a bit more complicated. It requires the use of tools to insert the tubing into the coupling body. Connections of this type are commonly used in high-pressure applications.

Maintaining your pneumatic coupler

Pneumatic couplers are an essential part of many industries, so it is important to keep them well-maintained. There are a few simple steps that can be taken to ensure that your pneumatic coupler remains in good condition.

The first step is to make sure that the coupling is properly installed. If the coupling is not installed correctly, it can cause problems such as leaks or disconnections. The second step is to regularly check the coupling for any damage or wear. If any damage is found, it is important to repair or replace the coupling as soon as possible.

The third step is to keep the coupling clean. A build-up of dirt and debris can lead to problems such as clogs or reduced performance. It is important to clean the coupling regularly to prevent these issues from occurring.

By following these simple steps, you can ensure that your pneumatic coupler remains in good working condition.

Pneumatic coupler troubleshooting

Pneumatic couplers are an essential part of many industries and it is important to keep them well-maintained. There are a few simple steps that can be taken to ensure that your pneumatic coupler remains in good condition, such as regularly checking the coupling for damage or wear and keeping it clean.

If you find that your pneumatic coupler is not working properly, there are a few troubleshooting tips that may help you fix the problem.

One of the first things you should check is the pressure of the air supply. If the pressure is too low, the coupler will not be able to make a secure connection. It is also important to check the condition of the O-rings. If they become damaged or worn, they must be replaced.

If you have checked the pressure and O-rings and the coupler still isn't working, it may be time to call a professional.